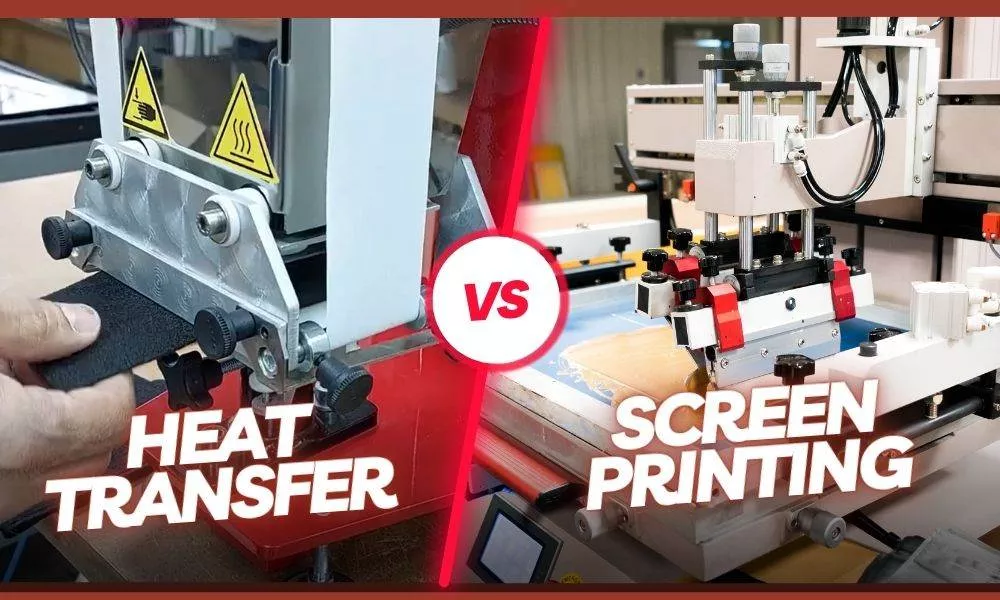

What is a heat press machine?

A heat press is a versatile printing machine that uses a combination of heat and pressure to transfer designs onto different surfaces. It consists of three main components: a heated platen, which can be flat or curved, a base, and a control panel. Heat presses come in various sizes and configurations, allowing for customization based on specific printing requirements.

How Do Heat Transfer Printing Machines Work?

The heat press process involves a straightforward series of steps:

Design Creation: Begin by creating or obtaining the desired design using graphic design software or by sourcing pre-made designs.

Printing: Print the design onto transfer paper using a compatible printer and ink. Ensure the design is reversed, as it will appear mirrored on the final product.

Preparing the Heat Press: Set the desired temperature and time on the control panel of the heat press. The optimal settings vary depending on factors such as the material being used and the type of transfer paper.

Positioning the Design: Place the transfer paper with the design facing down onto the surface to be printed. Secure it in place using heat-resistant tape if necessary.

Applying Heat and Pressure: Close the heat press and allow it to apply heat and pressure to the design and the substrate. The combination of heat and pressure activates the transfer process.

Transfer Completion: Once the set time has elapsed, open the heat press and carefully remove the transfer paper. The design should now be successfully transferred onto the substrate.

Types of Heat Transfer Printing Machines

There are different types of heat transfer printing machines available, each suited for specific applications and materials. The three main types are:

Sublimation Heat Transfer Printing Machines

Sublimation heat transfer printing machines are commonly used for printing on fabrics, such as polyester or blended fabrics. The process involves using heat to convert special sublimation inks from a solid to a gas, which then permeates the fabric and binds with its fibers, creating vibrant and long-lasting prints.

Vinyl Heat Transfer Printing Machines

Vinyl heat transfer printing machines utilize heat and pressure to transfer pre-cut vinyl designs onto various materials. This method is often used for creating designs with solid colors or intricate details. Vinyl transfers offer excellent durability and are popular for creating personalized garments and accessories.

Heat Press Machines

Heat press machines are the most common type of heat transfer printing machines. They consist of a heated platen, which can be operated manually or automatically. Heat press machines are versatile and suitable for a wide range of applications, from apparel and accessories to promotional products.

Advantages of Heat Transfer Printing Machines

Versatility and Flexibility

Heat transfer printing machines offer unparalleled versatility and flexibility in the printing industry. They can transfer designs onto a wide range of substrates, including fabrics, ceramics, metals, plastics, and more. This versatility allows businesses and individuals to explore various creative applications and customize products according to their specific needs. Whether it’s creating personalized apparel, promotional items, or unique crafts, heat transfer printing machines offer the flexibility to bring ideas to life on diverse surfaces.

High-Quality Output

One of the significant advantages of heat transfer printing machines is the ability to produce high-quality prints with exceptional clarity, vibrancy, and detail. These machines use advanced technology to ensure accurate color reproduction, sharp lines, and fine gradients. The heat and pressure applied during the transfer process facilitate the adherence of the design onto the substrate, resulting in long-lasting and durable prints. The high-quality output achieved with heat transfer printing machines makes them a preferred choice for professionals and businesses seeking professional-grade results.

Cost-Effectiveness

Heat transfer printing machines offer a cost-effective solution for both small-scale and large-scale production. Compared to traditional printing methods like screen printing, heat transfer printing requires minimal setup and cleanup time, making it more time-efficient and cost-efficient. The ability to produce prints on-demand allows for better inventory management and reduces the risk of overstocking or wastage. Additionally, heat transfer printing machines enable printing in small quantities without compromising on the quality, eliminating the need for bulk orders and excessive inventory. This cost-effective approach makes heat transfer printing machines suitable for businesses of all sizes and budgets.

Customization

Heat transfer printing machines offer the advantage of customization, allowing businesses to provide personalized products tailored to individual preferences. With the ability to print names, logos, and unique designs on various items, these machines enhance customer satisfaction and create a sense of exclusivity.

Applications of Heat Transfer Printing Machines

Heat presses find extensive use in various industries and settings, including:

Apparel Printing

Heat presses are widely employed for apparel printing, such as creating custom t-shirts, jerseys, hats, and uniforms. The ability to print intricate designs, logos, and vibrant colors onto fabric makes heat presses indispensable for garment decorators and fashion entrepreneurs.

Sublimation Printing

Sublimation printing, a popular technique in the industry, relies on heat presses for transferring designs onto specialized sublimation papers. These designs are then transferred to polyester-based materials, such as mugs, phone cases, and mousepads, resulting in high-quality, full-color prints.

Home Décor and Accessories

Heat presses also play a significant role in the production of home décor items and accessories. From personalized pillows and canvas prints to ceramic tiles and wooden signs, heat presses allow for intricate designs to be easily applied, enhancing the aesthetic appeal of various objects.

Factors to Consider When Choosing a Heat Transfer Printing Machine

Test and Calibrate: Before undertaking any major project, it is essential to test the heat press settings on similar materials to achieve optimal temperature and pressure.

Fabric Considerations: Different fabrics require specific heat press settings, so take into account the fabric type, thickness, and any special care instructions.

Proper Alignment: Accurate placement of the design on the substrate is crucial. Consider using alignment tools, such as rulers or laser guides, to achieve precise positioning.

Pressure Distribution: Ensure even pressure distribution across the entire surface by using a heat press with adjustable pressure settings. Uneven pressure can lead to inconsistent transfers.

Maintenance and Cleaning: Regularly clean the heat press platen and remove any adhesive residue or ink buildup. Lubricate moving parts as per the manufacturer’s recommendations to maintain smooth operation.

Tips for Using Heat Transfer Printing Machines Effectively

Prepare Your Design and Material: Ensure that your design is properly prepared and optimized for heat transfer printing, and choose the appropriate material that is compatible with the heat transfer process.

Set the Correct Temperature and Pressure: Adjust the temperature and pressure settings on the heat transfer printing machine according to the recommended guidelines for the specific material and transfer paper being used.

Ensure Proper Alignment: Align the transfer paper and substrate accurately to ensure that the design is positioned correctly and covers the desired area.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions and guidelines for operating the heat transfer printing machine to ensure optimal results and avoid any potential issues.

Troubleshooting Common Issues with Heat Transfer Printing Machines

Uneven Printing: If you encounter uneven prints or blurry images, check that the substrate is flat and properly positioned. Ensure the pressure and heat settings are adjusted accurately for the specific material.

Color Fading or Bleeding: To prevent color fading or bleeding, use high-quality transfer paper and inks. Ensure the substrate is suitable for the chosen heat transfer method and follow proper curing instructions.

Transfer Misalignment: Check if the transfer paper and garment are properly aligned before pressing, ensure the heat press machine is leveled, and use alignment tools such as registration marks or heat-resistant tape for accurate positioning.

Heat Press Malfunctions: Inspect and troubleshoot common issues like uneven heating, inadequate pressure, or faulty temperature control by checking the heating elements, pressure adjustment, and temperature settings, and consult the manufacturer’s manual for specific instructions.

Inconsistent Temperature or Pressure:If the temperature or pressure varies during printing, resulting in inconsistent transfers, double-check the machine’s settings and make necessary adjustments. Consider using a heat press machine with precise controls.

Conclusion

With its versatility, durability, and customization capabilities, the heat press is a powerful tool for transferring designs onto various surfaces. By understanding its functionality and following best practices, you can achieve remarkable results in your printing endeavors. At Innotransfers, we provide top-quality heat presses and expert guidance to support your printing needs. Take advantage of this remarkable printing technology and unleash your creativity!

FAQ

How to heat transfer vinyl and print without circuit machine?

To heat transfer vinyl without a circuit machine, you will need a few supplies: heat transfer vinyl (HTV), a cutting tool like scissors or a craft knife, a heat source like an iron or a heat press, and a protective sheet such as parchment paper or a Teflon sheet.

What type of printer is used for heat transfers?

Dye-sublimation printers are designed specifically for heat transfer applications and use special sublimation inks. These printers transfer the ink onto transfer paper, which is then heat-pressed onto the garment.

Is heat transfer printing suitable for all colors and fabrics?

Heat transfer printing is generally suitable for a wide range of colors and fabrics, including cotton, polyester, blends, and fabrics with a polyester coating. It works on both light and dark-colored fabrics