We want customization to create our aesthetic goods and promote individuality. The T-shirt category is an attractive section with a versatile concept in the textile fashion business. Heat transfer printing has been popular for several brands seeking unique prints. It originated in the late 1960s and has progressed from simple plastisol transfers to crisp digital technology with improved inks and heat press systems, making them more emissive on various materials. Later, sublimation and eco-solvent inks improved print quality while meeting today’s environmental requirements. Now is the time to understand the fascinating aspects of heat transfer printing on T-shirts.

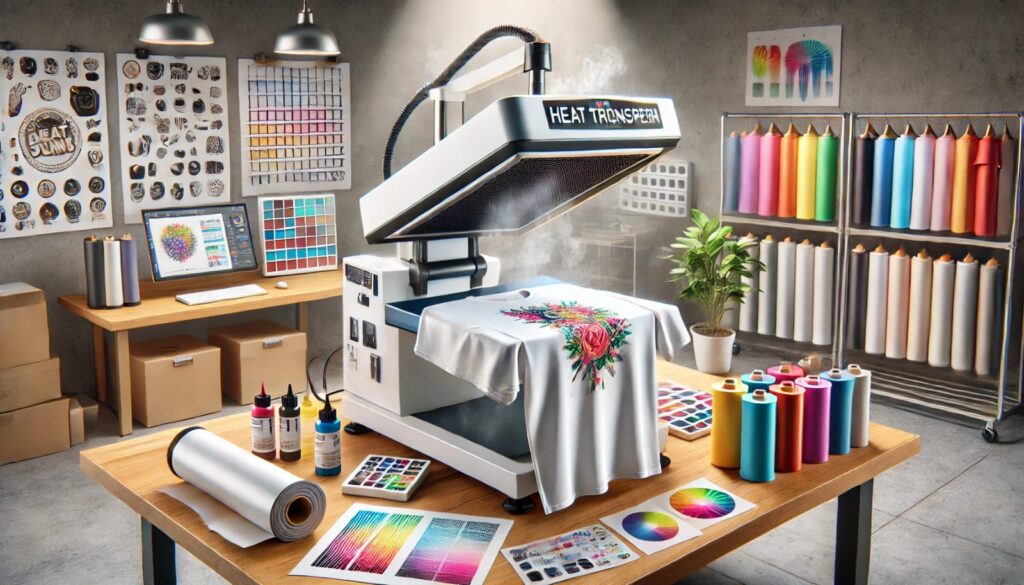

What is Heat Transfer Printing?

Heat transfer printing is one of the flexible approaches to printing as it entails using heat and pressure to transfer the printed design from a paper coated with ink to the fabric’s surface. This technique is most popular because it creates high-quality, high-clarity graphics on virtually any substrate. Heat transfer printing is of various kinds such as Vinyl Heat Transfer (HTV)printing which involves cutting out designs from vinyl-coloured sheets. Digital heat transfer printer involves using inkjet or laser printers to print the designs on the transfer paper and Sublimation heat transfer on polyester as the dyes penetrate the fabric. These flexible methods make heat transfer printing a desired process for custom apparel.

Popular Brands are Using Heat Transfer Printing

Renowned brands and companies have incorporated heat transfer printing to give life to T-shirt artwork. A brand I know is Custom Ink. It is a top online custom apparel retailer focusing on customized T-shirts. For their products, they use heat transfer printing, giving customers a wide selection of designs to help individuals and organizations establish their personalized goods.

Teespring, now called Spring, allows users to create products like T-shirts. Using heat transfer textile technology, it has become a great platform for independent artists and other enthusiasts who want to make money from their designs without investing a lot of money upfront.

Printful can also be counted as one of the key market players that provide print and fulfillment services designed basically for e-commerce stores. They have heat transfer printing for their T-shirts which are visually appealing and can easily blend with the major online stores.

Heat transfer printing techniques are also used by Redbubble, an online market that connects artists with buyers and allows individual artists to showcase their designs on T-shirts and other products. With this platform, an independent and professional designer can market their artwork on textiles in the best way possible, with proper heat transfer screen printing done on the required textile.

Last but not least, Zazzle specializes in personalized garments products. The use of heat transfer printing also creates more particular options for the customer, making promotions of more personalized products even more appealing.

Heat Transfer Printing Related to all the types of machinery:

Flatbed Heat Press: Perfect for imprinting on flat items such as T-shirts and sweatshirts.

Rotary Heat Press: uses a rolling drum that prints on fabric rolls at one time and is used in textile industries.

Vacuum Heat Press: Vacuum pressure is undoubtedly used to maintain a high level of pressure that easily fits the odd shapes of surfaces.

Sublimation Printers: Worked on polyester fabrics, these printers use thermo-sensitive inks that diffuse into the polyester fibers and are perfect for snatch and vivid colored prints on sport-related apparel and polyester-based textiles.

Heat Transfer Vinyl Cutters and Plotters: These cut designs are from heat transfer vinyl, items that are utilized for logos and letters.

Conveyor Heat Transfer Machines: It is used for producing a large volume of prints at a time in operations that need an unbroken supply of paper to produce gigantic volumes of prints quickly.

3D Sublimation Heat Press: Specifically designed for a mug, phone case, and any other irregularly shaped 3D items, spreading the heat equally around curves.

Laser Transfer Printers: Using laser transfer printing techniques provides more refined and clear cuts on the designs mainly on black and other colored fabrics and diverse embossing materials permitting intricate prints.

Direct-to-Film (DTF) Transfer Printers: These are relatively newer models and are capable of delivering photo-quality film-based transfers that can be thermally printed onto varieties of fabrics including cotton and polyester blended ones with the help of a heat press.

Automatic and Pneumatic Heat Presses: These presses apply heat in the required method and control its duration, which is prevalent in high throughput applications that demand accuracy and productivity.

How to Heat Transfer Print on T-Shirts

Design Creation: The process starts with designing the product on a computer through digital graphic design or photography. This design can be carved to details, and gradients and also contain multiple colors for best customization.

Printing the Design: After the final design is made, it is then placed onto specific transfer paper. In case of sublimation, vinyl, and inkjet transfers a suitable printer is chosen accordingly. For instance, sublimation printing implies that the material must be printed with sublimation inks and on sublimation transfer paper.

Prepping the T-shirt: The T-shirt is spread wide open, and the side that has the designs should be lined up well such that the surface before the heat press is laid on is smooth and clean. This way you are sure that the print is going to stick on the surface well without forming blotches.

Positioning the Heat Transfer Paper: The transfer paper is then placed face downwards on the T-shirt and the printed design is to be placed on this side. This step must be done properly to ensure that no misaligns as once heat has been applied, then the alignment cannot be changed.

Applying Heat and Pressure: A heat press machine is used to set the temperature and pressure which will almost always be determined by the transfer paper used. The press is then closed with heat and pressure allowing the ink to transfer from paper to T-shirt. It depends on which type of transfer is being applied (for sublimation, it might use around 400°F for 40- 60 seconds, while vinyl is at lower settings than this).

Peeling the Heat Transfer Paper: At the end of the time, the heat press is raised and the transfer paper is removed, either while still hot for some papers, or cold. When doing a hot peel, the procedure can be done at once, for a cold peel, one has to wait for the paper to cool down.

Final Curing and Inspection: Some designs may require additional curing under a heat press or drying rack to ensure durability. The T-shirt is inspected for quality, ensuring the design is transferred evenly, with no smudges or fading.

Global Import and Export

The global market for heat transfer printing technology has grown significantly. This growth is occasioned by the growing fashion niche market and improvements in technology that ease the process of printing on fabrics. The heat transfer printing market reached USD 3 billion in 2023 and is expected to reach USD 4.5 billion by 2028, with a CAGR of around 7%.

The Advancement in Heat Transfer Printing Technology

Today’s heat transfer printing has come a long way since its origins with plastisol transfers and simple heat applications. Current technological breakthroughs have enabled specific, environmentally friendly technologies such as water-based or eco-solvent ink, making the process more sustainable. Recent heat press models include enhanced heat dispersion throughout the surface, as well as controls that allow for programming and fast cooling. Dye-sublimation technology provides high-quality bright patterns that are heat-sealed into fabrics, making them ideal for athletic and polyester garments.

However, the use of heat transfer printing has thus become a fundamental method used in the T-shirt industry, allowing brand owners to give clients satisfaction in an effective and high-quality style. Because this style has been effectively adopted by various amazing enterprises, as well as a strong and crucial web of international trade contacts that helps preserve the machinery import-export balance, this section of the customized textile industry has a promising future.