One of the most significant advances in the custom printing world has come in the way of full color transfers, allowing almost anyone to create stunning graphics on required surfaces. Thanks to its ability to create delicate, multi-colored designs with considerable accuracy, this method is becoming increasingly popular among entrepreneurs and individuals. Full-color transfers are perfect for apparel, promotional, and other custom products because of their first-rate quality and ease of application.

Market Overview

The global digital printing market, including full-color transfers, was valued at $38.07 billion in 2023. It is expected to grow at a CAGR of 6.2% from 2024 to 2030 and reach $57.03 billion in 2030. In detail, the market for printing transfer paper is expected to rise from $12.94 billion in 2024 to $17.44 billion in 2032, with a CAGR of 3.8%.

Use of full-colored transfers

Numerous industries and sectors recognize full-color transfers because of the flexibility of the product and its appearance. In the apparel sector, they are suitable for making T-shirts, hoodies, and caps with specific designs or even photographic imprints. Sports teams, as do event managers and organizers, also prefer full-color transfers for original uniforms and promotional items due to the versatility of the technique, where logos, players’ names and details emblems are easily printed and engraved on products. Besides the apparel sector, full-color transfers are required for promotional products like mugs, tote bags, and notebooks.

Marketing and promotional products: These items are used in marketing exercises and giveaways by companies as people mostly look for vibrant and long-lasting prints. Another flourishing field in using full-color transfers is the home décor industry and products such as pillowcases, tablecloths, and wall art. They also apply to corporate branding, where companies use general office items, staff wear and equipment, and own computers and gadgets with specific company logos.

fig: Customized design for full-color transfers

Who Uses Full Color Transfers?

According to the small business owners interviewed for the custom merchandise industry, this method is cheaper than other methods, especially for short or one run. It is also convenient for large-scale manufacturers to use the equipment, especially when manufacturing personalized or small-sized batches.

Craft lovers and enthusiasts consider full-color transfers suitable for do-it-yourself projects since the process is easy and the outcome is professional. Also, full-color transfers are helpful when designing sports teams’ uniforms, banners, and other merchandise since they create a stunning image that the users can easily perceive. This accessibility of the technique makes it one of the ideal solutions for consumers.

Full Color Transfers Paper & Types

Transfer paper is essential in the process. The two main types are:

1. Inkjet Transfer Paper:

This paper is specially created for inkjet printers to work with it to produce high-quality full-color prints. This product is suitable for all types of white or black fabrics.

2. Sublimation Transfer Paper:

Sublimation transfer paper fits well with polyester fabrics and coated surfaces and provides bright and non-fade images.

3. Laser Transfer Paper:

Unique papers compatible with the laser printer provide highly accurate results on detailed designs.

fig: laser transfer paper for full-colour transfers

The Role of Transfer Paper

Transfer paper is an essential element in full-color transfers for design purposes. Several types of transfer paper are available in the market, each capable of meeting a specific need. A versatile substrate for inkjet transfer, inkjet transfer paper delivers full-color reproduction and good compatibility with a broad range of material types, from light to dark.

Sublimation transfer paper can also be used and is preferred for polyester-based fabrics and coated surfaces. It is fade-resistant, making it produce long-lasting and high-quality prints. Another substrate is the laser transfer paper, which is much better defined in its ability to create sharp lines and dense images. Using the correct type of transfer paper to get the right results becomes essential.

Process of Full-Color Transfer Printing:

1. Design Creation:

Some of them are done on computers with the help of Tools like Photoshop or Illustrator.

2. Printing:

Using an ordinary printer compatible with the transfer paper already used in the design, the design is printed on the transfer paper.

3. Preparation:

In this case, the substrate may be the fabric; before the coating process, it undergoes cleaning and smoothening.

4. Heat Transfer:

Depending on the fabric and the design, heat is applied evenly on the fabric by a heat press method, and pressure is applied for the correct amount of time.

5. Most satisfying Peeling:

Transfer paper is then separated from the item, leaving only the imprinted design on the substrate.

Advantages of Full-Color Transfers

Full-color transfers make them very appropriate for reproducing graphics and pictures on photographic prints. Moreover, the method is cheap for small-scale production because it does not require much preparation and equipment, as observed in techniques such as screen printing.

Similarly, full-color transfers are very quickly printable, and thus, they can be applied to almost every fabric, like cotton or synthetic, such as polyester, hard materials like ceramics, and metals. Additionally, green inks and transfer papers can be used to reduce the automated green impact of the process.

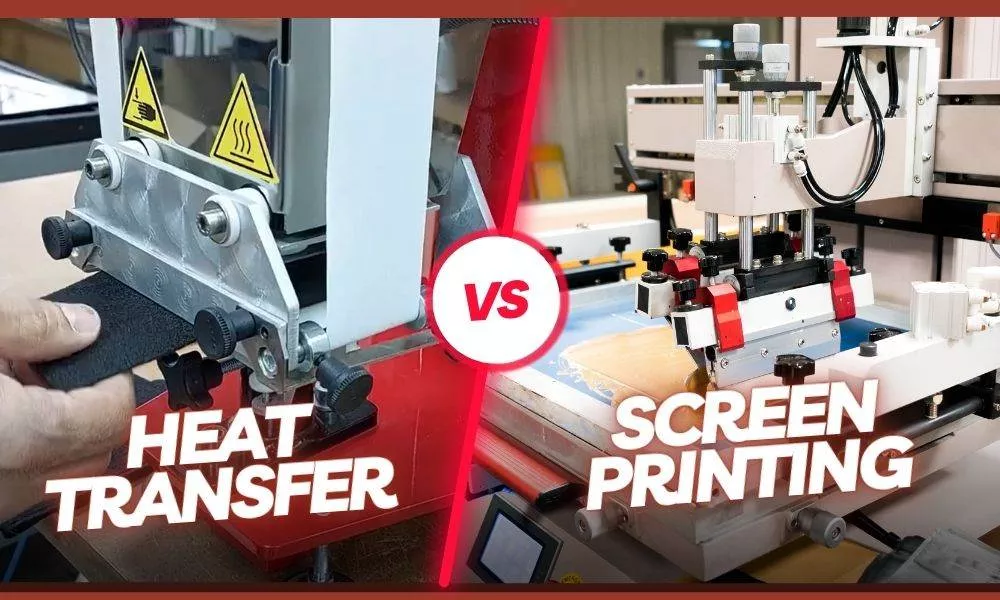

Full-Color Transfers Vs. Screen Printing

Full-color and two-color transfers serve as means to a desired end, which is custom printing, but they are significant and different in serving this need. Plastic full-color transfers boast of resourcefulness regarding small parts, detailed digitized multi-color designs, and also because they require the minimum setup time. That is why screen printing is more appropriate for mass production, as the costs and quantity are lower.

Regarding durability, screen printing can work longer than full-color transfers on fabrics. However, full-color transfers are more creative when choosing substrates because thermo-transfer paper can be used in different styles. Thus, one decides which method to use depending on the type of project to be developed.

Tips for Beginners

1. Ensure you get a good quality heat press machine to achieve the actual effect.

2. Transfer papers differ, and one has to try various of them to determine which suits one’s custom best.

3. The idea is to begin with simple graphics to get a footing to handle complex ones.

4.It most importantly requires temperature and pressure to observe the manufacturer’s signed directions.

Conclusion

Modern, accessible, and effective full-color printing has revolutionized custom printing solutions. For the small business that wants to create promotional merchandise or the craftsperson who wants to do a project, full-color transfers are the tools to get the job done. Although screen printing is today the most popular due to its durability and high resolution, full-color transfers are equally notable for their diversified character in design complexities, the small number of T-shirts to be decorated, and the variety of materials. Subsequently, with the emerging technological revolutions, full-color transfers are also set to improve and become an indispensable accessory in custom printing services.