Brand management in fashion and textile products has emerged as a competitive strategy due to the dynamics in fashion. These labels are redesigning garment packaging, integrating novelty, flexibility, and eco-friendliness strategies. Let’s look at all the factors that make heat transfer labels a future apparel branding category.

What are Heat Transfer Labels?

Tags or tagless heat transfer labels are traces of a brand logo or customized message stating care instructions directly onto the fabric with pressing heat. Unlike conventional sewn-in tags that may be thick and cause some discomfort, heat transfer labels are clean-cut, hard-surfaced, and almost indiscernible. Labels can hold everything from a brand’s icon and measurements to washing instructions, quick response codes, and intelligent linking.

Latest Trend & Uses

Using heat transfer label is not a temporary trend but a new way of responding to consumers’ expectations and requirements. Let’s see what makes labels essential for heat transfer:

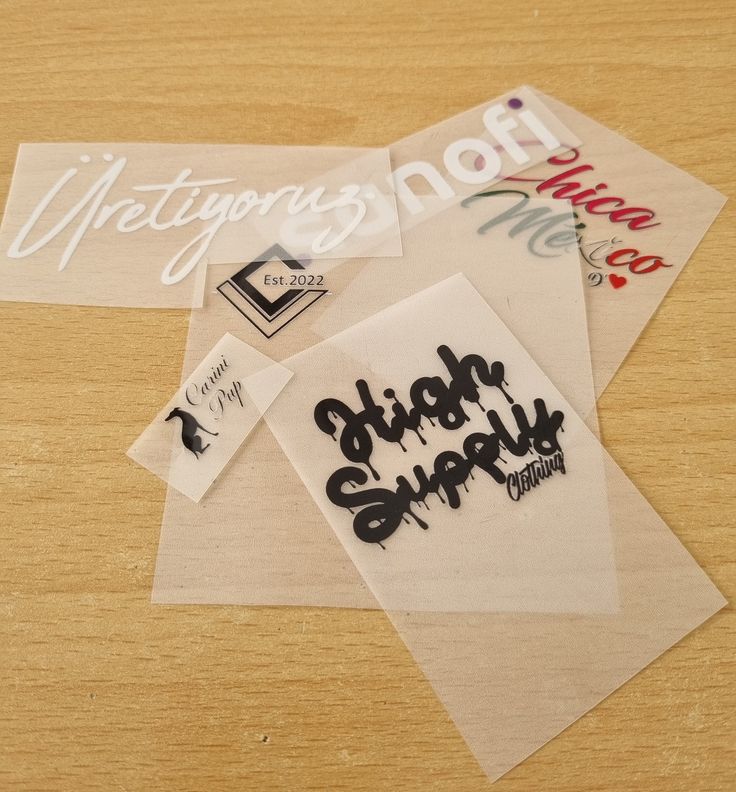

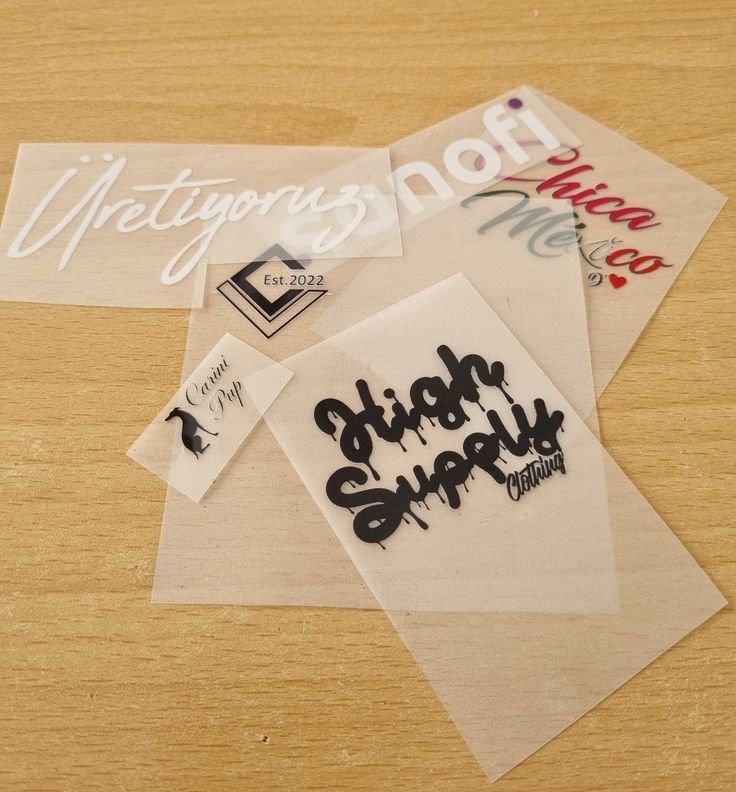

fig: Iron on Heat Transfer Labels

Comfort

People with sensitive skin usually find the tags irritating sometimes. Heat transfer labels do away with the discomfort felt by labels with tags, allowing you to be as comfortable as possible without overstepping on style.

There is no clutter, and it looks very professional.

The material used for these labels is not bulky, and one cannot even feel the labels on the garment. These user-friendly benefits help renowned sports brands create an intricate and sophisticated look.

Durability and Longevity

Heat transfer labels are made with a unique purpose to ensure they do not fade, crack, or peel, especially when the labels are washed several times, dried, or used frequently. Heat transfer labels can preserve their form and utility throughout the garment’s life cycle.

Eco-Friendly Solutions

Nowadays, sustainability emerges as a trendy topic of discussion in the fashion industry, and heat transfer labels are being upgraded with time. Labels have added innovations, such as water-soluble inks for printing heat transfer, biodegrading papers, and recyclable films.

Versatility Across Fabrics

While heat transfer labels can be applied to traditional materials like cotton and polyester, they can also stick to spandex and other related products and applications that can increase product versatility in the textile industry.

Some of the Heat Transfer Labels include:

Heat transfer labels are versatile and can be identified in different segments of the apparel sector. Their adaptability makes them suitable for what? Not too hard to answer. Let’s find the answer.

Sportswear: Heat transfer labels Offering versatility and longevity, specifically for athletes and fitness fashion-related clothing brands.

Kidswear: Providing a comfortable, non-irritative feel for toddlers and babies. These brands are making parents purchase.

Luxury Apparel: To further refine sophisticated luxury wear while discreetly providing clear labeling solutions.

Promotional Clothing: Branded merchandise to another level by offering quality label finish. Apart from garments, these tags are also used in accessories, footwear, and technical fabric, which demonstrate labels’ versatility in different areas.

fig: Customized heat transfer logo labels

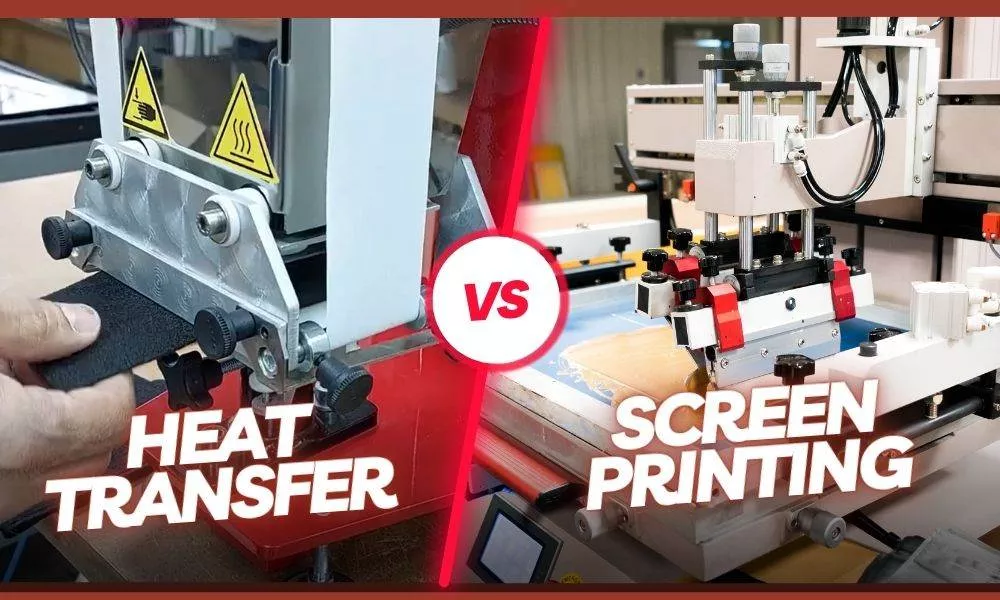

How Heat Transfer Labels are Creating & Applying?

Step-by-Step Process

Step 1: Design Creation

A specific heat transfer film is printed to obtain the desired label design. Labels can be character logos, text, and other forms of complex artwork that are both creative and unique.

Step 2: Placement on the Garment

The heat transfer film is placed precisely on the fabric where it wants to be positioned.

Step 3: Heat Application

A heat press Innoprinter machine applies heat and pressure to the transfer film to twig the required and customized design. Examples: InnoPrinter MK1, InnoPrinter MK2.

Innoprinter is designed to increase efficiency, capable of producing up to 500 prints per hour.

Step 4: Film Removal Technique

The transfer film is removed after the label is attached, and the imprint appears as part of the fabric.

It may look like a simple but highly efficient approach to maintaining quality control during high production.

Why Brands Should Use Heat Transfer Labels?

The answer is here:Heat transfer labels offer many advantages for brands looking to stay ahead in a competitive market.

Cost-Effectiveness

While the initial investment of heat press machines may be relatively expensive, the savings in time and labor are more than what is paid for this system of manufacturing heat transfer labels.

Scalability

Thus, heat transfer labels will be as effective in a business that produces 50 garments as in a business that produces 50,000 garments due to their quality.

Sustainability: The current generation’s idea is to embrace environmentally friendly policymakers; heat transfer labels align with this.

Improved Consumer Experience: This aligns with customer needs as customers are willing to go for more comfort and durability of products.

Innovations and Future Prospects

Eco-Friendly Materials

The material players are developing biodegradable transfer films and employing non-toxic inks to meet the growing environmentally friendly market needs and international sustainability objectives.

Smart Integration

As more attention is paid to smart textiles, heat transfer labels are being improved by adding QR codes, NFC chips, and other elements. Such aspects allow garments to share product information, care instructions, or brand history with the wearer through the phone.

Increased Customization

Future developments will extend the capabilities of contemporary hyper-personalization procedures, rendering more influence to brands and consumers in designs, textures, and application styles.

Whether you are just starting and have your brand in the field of fashion, or as the case is with many more experienced designers, heat transfer labels will allow you to create an excellent first impression of your work. So, as the industry progresses, having such progressive approaches will enable your brand to remain market-relevant and conform to customer needs.

It is time to go on to a new level of apparel branding with heat transfer labels and reach out to your customers differently.