Introduction to Digital Printing

Digital printing has become a dominant force in the world of printing due to its efficiency, flexibility, and ability to handle complex designs with precision. Unlike traditional printing techniques such as screen or offset printing, which involve manual setup and longer processing times, digital printing offers a fast, cost-effective solution for both large and small print jobs. Whether you’re printing custom T-shirts, personalized packaging, or posters, digital printing delivers unmatched quality.

What is Digital Printing?

Digital printing is the process of transferring digital images directly onto a variety of media surfaces such as paper, fabric, or plastic using a computer and specialized printing equipment. Unlike traditional printing, digital printing does not require printing plates, making it an ideal choice for on-demand and short-run production. The technology behind digital printing enables high-resolution prints with sharp detail and vibrant colors.

Types of Digital Printing Methods

There are several types of digital printing methods, each with its own advantages depending on the application. Let’s explore the most common types:

Inkjet Printing

Inkjet printing is one of the most widely used forms of digital printing. It works by spraying tiny droplets of ink directly onto the material being printed. This method is commonly used for paper products, posters, and even textiles.

- Common Applications: Posters, brochures, fine art prints

- Pros: High-quality images, cost-effective for short runs

- Cons: Slower than other methods for high-volume orders

Laser Printing

Laser printing uses a laser beam to create an image on a drum, which is then transferred to paper through a heat process. It’s commonly used for printing text documents but can also handle graphic designs.

- Applications: Business documents, labels, packaging

- Pros: Speedy printing, ideal for high-volume text-based work

- Cons: Less effective for high-resolution images

Dye Sublimation Printing

Dye sublimation involves using heat to transfer dye onto a surface such as fabric or plastic. The process creates vibrant, durable prints, often used for textiles and promotional items.

- Popular Use Cases: T-shirts, mugs, banners

- Pros: Long-lasting, fade-resistant prints

- Cons: Limited to polyester fabrics or specially coated surfaces

UV Printing

UV printing uses ultraviolet light to cure the ink as it’s printed, resulting in sharp, detailed images on almost any surface, including wood, glass, and metal.

- Common Applications: Signage, packaging, promotional items

- Pros: Quick drying, suitable for non-porous materials

- Cons: Can be more expensive than traditional printing

Direct-to-Garment (DTG) Printing

DTG printing has revolutionized the fashion industry by allowing detailed, full-color designs to be printed directly onto garments like T-shirts, hoodies, and more.

- How it Differs from Screen Printing: Unlike screen printing, DTG allows for unlimited color choices and is perfect for small batch orders.

- Best Fabrics for DTG: Works best on cotton-based fabrics for vibrant and durable prints.

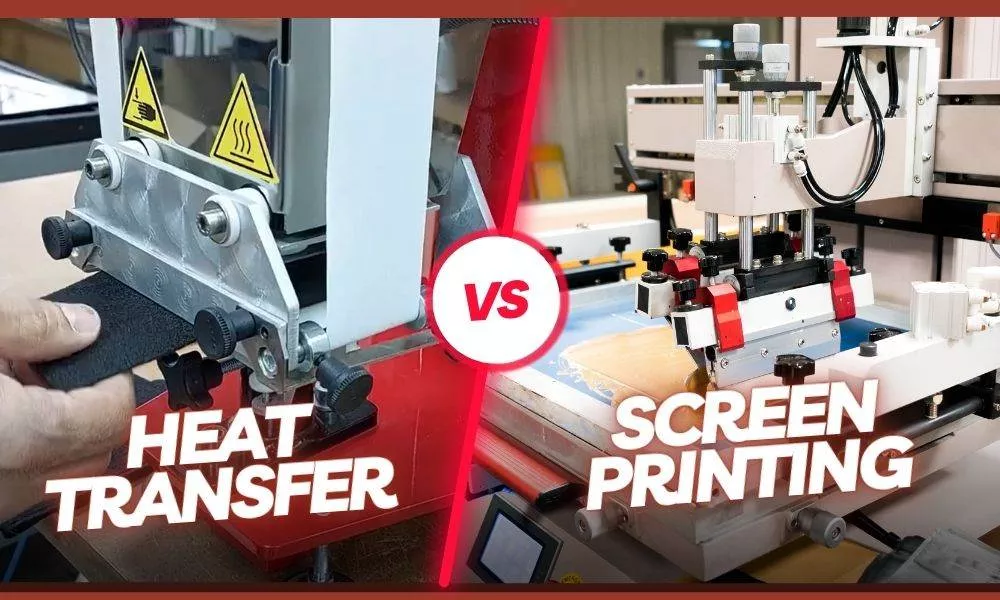

Transfer Printing

Transfer printing involves printing an image on a special transfer paper that is then applied to the desired surface using heat and pressure. This method is often used for fabric but can also be applied to hard surfaces like ceramic.

- Applications: Clothing, bags, ceramics

- Pros: Easy to use for custom designs

- Cons: Not as durable as DTG or dye sublimation

Comparison of Digital Printing Methods

- Inkjet vs. Laser: Inkjet is better for detailed images, while laser excels in speed and handling high volumes.

- Dye Sublimation vs. UV Printing: Dye sublimation is ideal for fabrics, while UV printing can handle a wider range of materials.

- DTG vs. Screen Printing: DTG is perfect for small, custom orders, while screen printing is better suited for large quantities with fewer colors.

The Future of Digital Printing

The digital printing industry continues to evolve with advances in technology. Automation, artificial intelligence, and sustainable practices are likely to shape the future, making digital printing even more efficient and environmentally friendly.

Conclusion

Digital printing offers a diverse range of methods to meet various needs, from high-quality fabric printing to eco-friendly packaging. Its flexibility, speed, and ability to produce stunning visuals make it an essential tool for businesses and artists alike. As technology advances, the possibilities of digital printing will only continue to grow.